Services

Welding Services

Weld overlaying for repair and maintenance for worn-out parts for various industries. Specialized welding services for low heat input deposition methods to reduce weld distortions.

We make the most effective use of advanced & automated welding processes for weld-overlaying. Some of the outstanding advantages of use of welding automation in the field of cladding are as follows.

Plasma(PTAW)

Plasma Tungsten ARC Welding (PTAW) is a thermal process for applying wear- and corrosion-resistant layers on surfaces of metallic materials. It is a versatile method of depositing high-quality metallurgically fused deposits on relatively low-cost surfaces.

Auto MIG - Cladding

Metal inert gas (MIG) welding—also known as gas metal arc welding (GMAW)—is an arc welding technique that involves continuously feeding a solid wire electrode through the welding gun to join two pieces of metal together.

Auto TIG - Cladding

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld.

Machining

A welding machine is a device used to join materials together. Welding machines produce heat that melts metal parts so that these parts can be joined. Thus, when it cools, it becomes a fixed and resistant joint.

Seal Welding

Seal Welding as Any weld designed primarily to provide a specific degree of tight- ness against leakage. The purpose of a seal weld may be to contain a fluid – either gaseous or liquid.

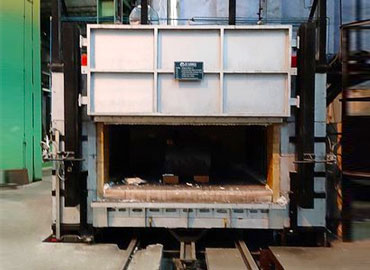

Heat Treatment Furnace - 18KW

Heat treatment furnaces are used to achieve these processes, which involve extreme heating or cooling to achieve their desired reaction.